WHAT IS INDUSTRIAL WATERPROOFING?

WHAT IS INDUSTRIAL WATERPROOFING?

INTRODUCTION

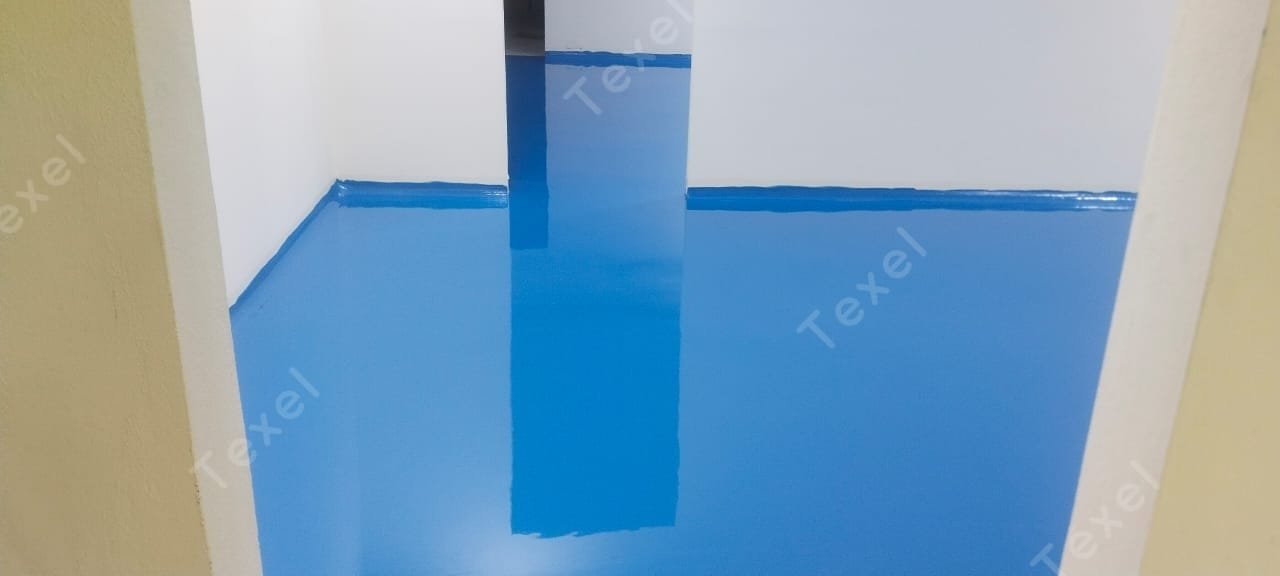

Industrial waterproofing is the process of applying materials and techniques

to protect structures, facilities, and surfaces from water intrusion,

preventing damage that can weaken buildings, equipment, and materials. It is

commonly used in environments where structures are exposed to water or

moisture, such as factories, warehouses, chemical plants, and storage

facilities.

WHY WATERPROOFING IS IMPORTANT IN

INDUSTRIAL AREAS?

Waterproofing is essential in industrial areas for several reasons,

primarily to maintain structural integrity, protect equipment, and ensure

safety. Here’s a breakdown of why it’s so critical:

v

Prevents Structural Damage: Industrial

buildings are often built with concrete and steel, both of which can

deteriorate when exposed to water. Waterproofing application protects these

materials from water infiltration, reducing the risk of cracks, corrosion, and

weakening of the structure.

v

Protects Machinery and Equipment: Many

industrial facilities contain expensive and sensitive equipment that can be

damaged by water exposure. Waterproofing system prevents leaks and flooding,

helping to protect machinery from rust, electrical failures, and costly

repairs.

v

Ensures a Safe Work Environment: Water

leaks can create slippery surfaces, leading to workplace accidents.

Waterproofing installation reduces the risk of slip-and-fall hazards, promoting

a safer environment for workers.

v

Increases Facility Lifespan:

Waterproofing installation helps to prevent early degradation of materials,

thereby extending the life of industrial facilities and reducing the frequency

of costly renovations or reconstructions.

v

Protects Stored Goods and Inventory: Many

industrial areas store goods or raw materials, some of which can be sensitive

to moisture. Waterproofing prevents these materials from becoming compromised

by mold, rust, or other water-related damage.

v

Reduces Maintenance Costs: By preventing

water damage, waterproofing application minimizes the need for frequent repairs, which

can disrupt operations and lead to costly downtime.

v

Controls Mold and Mildew: Industrial

settings with moisture issues can become breeding grounds for mold and mildew,

which can damage structures, affect air quality, and pose health risks to

employees.

Industrial waterproofing is a preventive measure that helps companies avoid

operational disruptions, save on maintenance costs, and create safer, more

resilient facilities.

CONCLUSION

Industrial waterproofing is a vital investment that protects facilities from water damage, enhances safety, and promotes longevity in industrial structures. By preventing water intrusion, waterproofing system helps safeguard critical equipment, maintain structural integrity, and reduce costly repairs or downtime. Effective waterproofing techniques not only prolongs the life of industrial assets but also creates a safer work environment, minimizing risks and supporting efficient operations.

Related Posts

Leave a Reply Cancel reply

You must be logged in to post a comment.